Technology

Technology

Wire straightening and cutting

Panel welding

Corrosion protection

Packing and transport

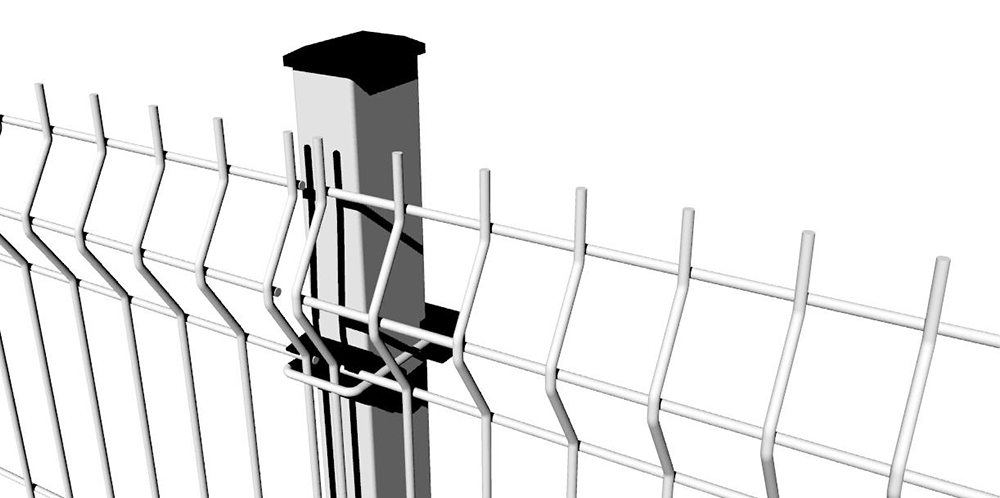

Brackets

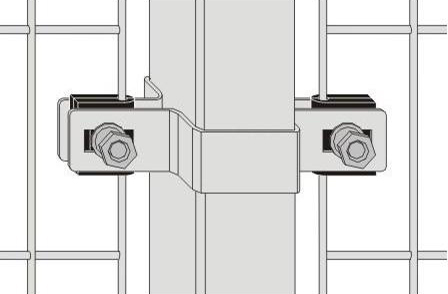

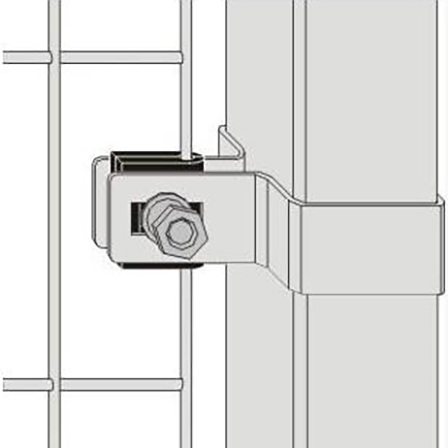

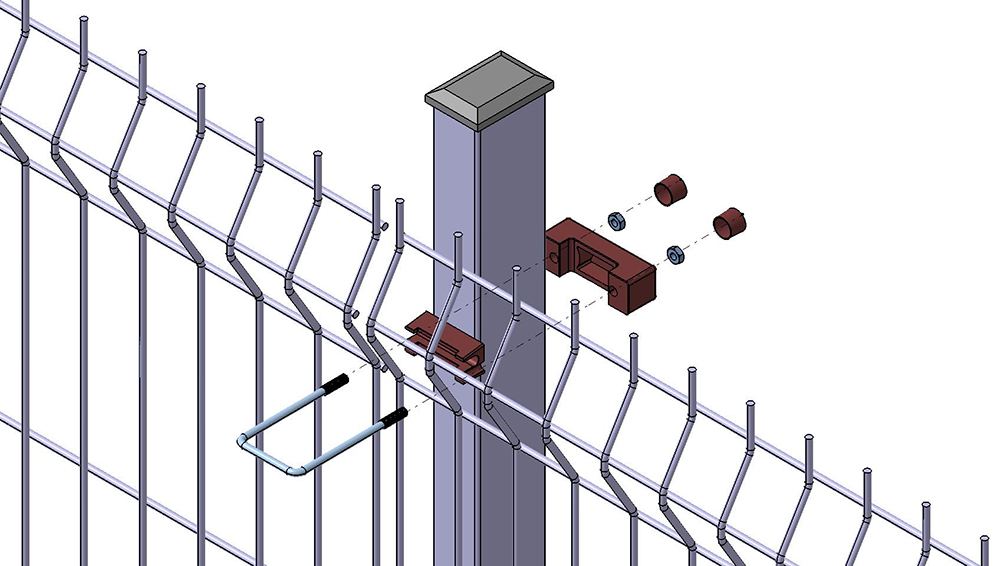

BRACKETS

- a) OM-1 - to join panels on the side of the posts

The standard bracket type is compatible with 60 x 40 section posts; at the special request of customers, we offer brackets for other square sections (e.g. 40×40, 80×80) or round sections (e.g. with diameters of 42 or 48 mm).

Depending on the fence line, there are three types of OM-1 brackets:

- • intermediate - the fence line is straight

- • corner - the fence line turns at an angle of 90º

- • end - the fence ends.

- b) OM-2 - to join panels in front of posts

Fence posts

FENCE POSTS

Fence posts are a vital component of panel fencing systems. Their correct fixture contributes to the durability and aesthetics of the entire fence. The posts in the TABAL product range are made of 40×60 galvanised steel sections, painted in our state-of-the-art powder coating shop. To meet the expectations of our customers, we offer posts of various height and wall thickness parameters.

Standard colours: green RAL6005, anthracite grey RAL7016, brown RAL8017, black RAL9005.

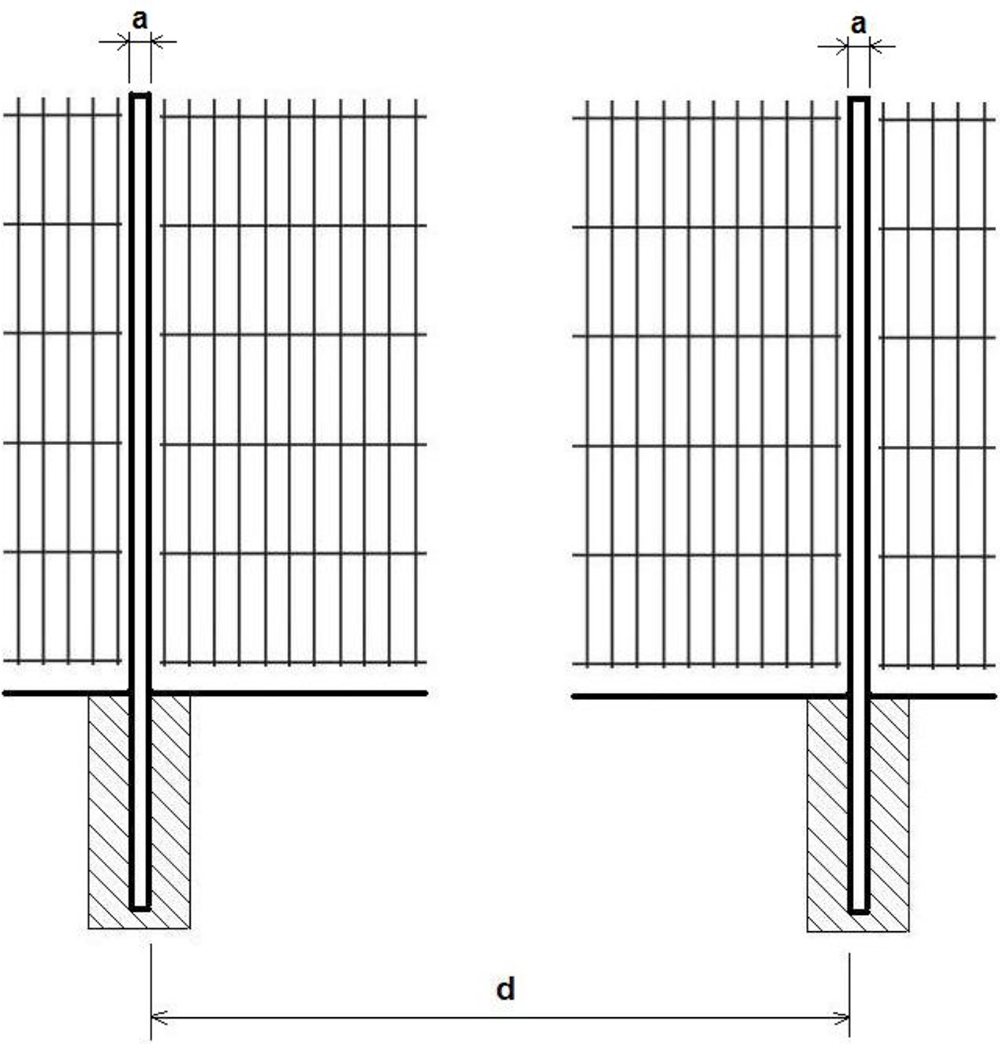

- • between posts with the use of OM-1 brackets (the axial distance between posts is 2.58 m)

- • to the post front - OM-2 brackets (the axial distance between posts is 2.51 m)

For the OM-1 bracket, d = 2540mm, so the axial distance between standard 40 x 60 posts is 2580 mm (40 mm wall from the fence front).

For the OM-2 bracket, d = 2470 mm, so the axial distance between standard 40 x 60 posts is 2510 mm (40 mm wall from the fence front).

As for the assembly of posts made of other sections, the axial spacing = d + a.

Techfence fencing

TECHFENCE FENCING

Our products

FENCE PANELS

ACCESSORIES

COMMERCIAL DEPARTMENT

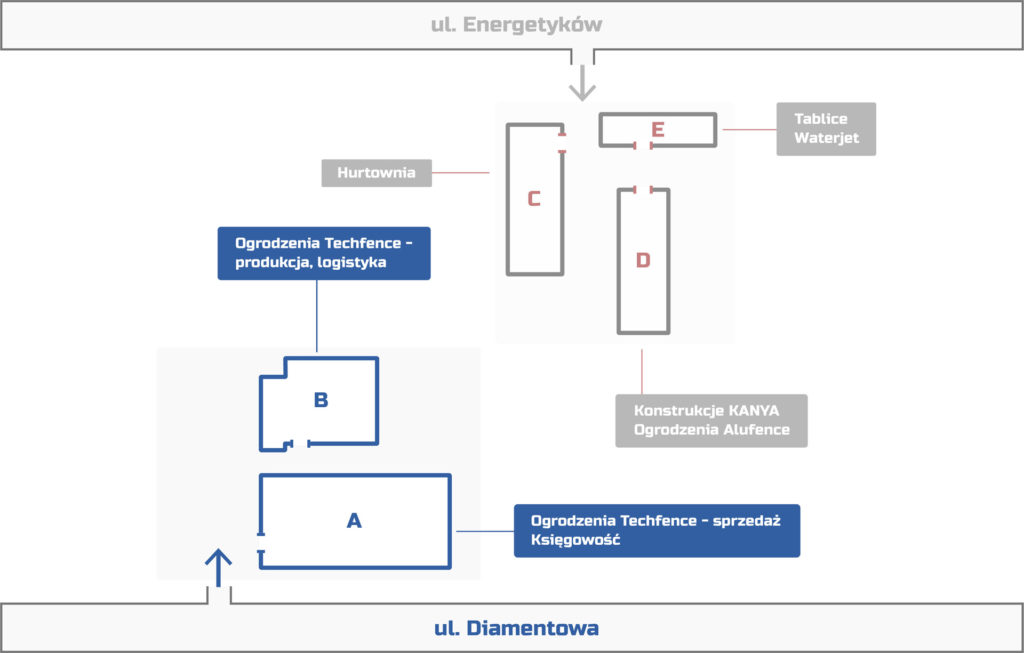

- 20-447 Lublin, ul Diamentowa 7A

- ogrodzenia@tabal.pl

COMMERCIAL DIRECTOR

- • Paweł Ligęza

- tel. 785 039 000

- tel. 81 745 55 49

- pligeza@tabal.pl

SALES DEPARTMENT

- • Patrycja Cholewa

- tel. 601 374 833

- tel. 81 745 55 37

- pcholewa@tabal.pl

- • Karol Latuszyński

- tel. 601 374 316

- tel. 81 745 55 47

- klatuszynski@tabal.pl

PRODUCTION DEPARTMENT

PRODUCTION DIRECTOR

- • Piotr Rykwa

- tel. 603 299 405

- tel. 81 745 55 45

- prykwa@tabal.pl

COATING SHOP MANAGER

- • Tomasz Lis

- tel. 882 341 015

- tel. 81 745 55 39

- tlis@tabal.pl

LOGISTICS SPECIALIST

- • Piotr Czapla

- tel. 697 094 404

- tel. 81 745 55 36

- pczapla@tabal.pl

- • Paweł Mituła

- tel. 81 745 55 38

- tel. 882 341 011

- pmitula@tabal.pl